Manage FF&E specification, procurement, and product data at scale. Take on bigger projects with confidence and grow your firm with Fohlio. Schedule a demo or book a consultation with one of our account managers to explore these features today.

When the pandemic hit, many AEC firms were left scrambling to finish projects on time. Among other concerns such as employees’ safety and a general economic downturn, architects, designers, and contractors also had to deal with supply chain issues.

According to Bjarke Ingels, COVID-19 exposed the stark shortcomings of existing supply chains. “One thing that we find intriguing is the idea of distributed just-in-time manufacturing capabilities,” Ingels told Dezeen in an interview.

One of his proposed solutions is to move the manufacturing process from “purpose-built factories to general capability and eventually to the maker hub on the block or the personal fabricator.”

While it’s definitely worth considering, it’s an idea that needs incubation. And in the meantime, you need solutions that can help you now and in the near future.

Here are three ways you can mitigate procurement delays with Fohlio.

Stay organized and anticipate.

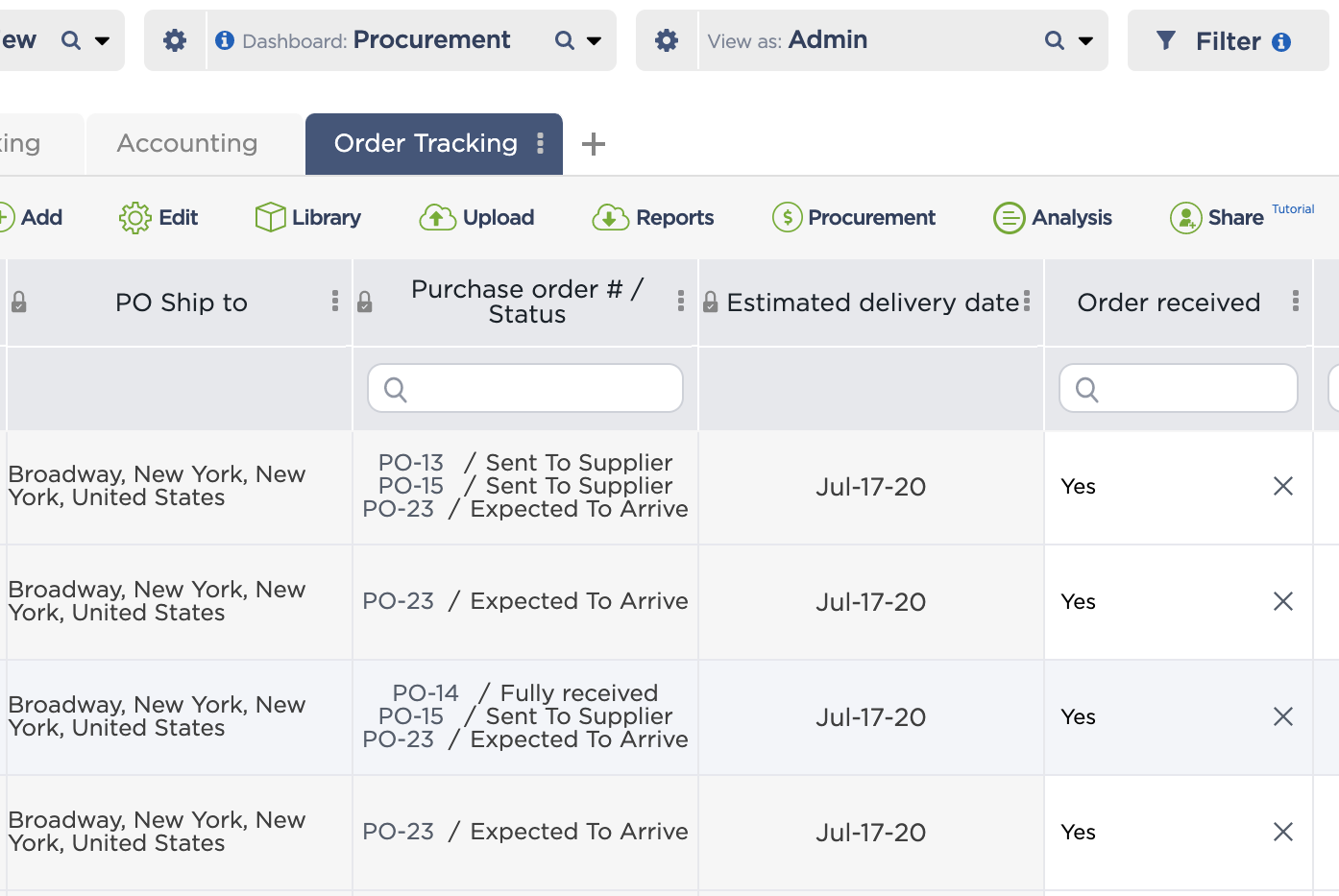

Keep your lead times, delivery dates, and installation schedules front and center — and all in one place. In your dashboard, create a tab specifically for timetabling. Include a column for when a certain material is needed onsite.

Next to that, set up columns for lead time, order status, expected delivery date, and projected quantity. You can even include a column to indicate how many days you have as an allowance for pivoting. For example: If it’s 14 days out from being needed on the project site and the order status still says your glass office fronts haven’t been shipped, then it may be time to put in a call to your supplier.

In worst-case scenarios, you may need to order from a different supplier. Or if a shipment is delayed, then you may want to look into moving around your project schedule. This way, you can give yourself the best chance of still finishing on time or not losing out on rented equipment or hired manpower.

Shore up agility.

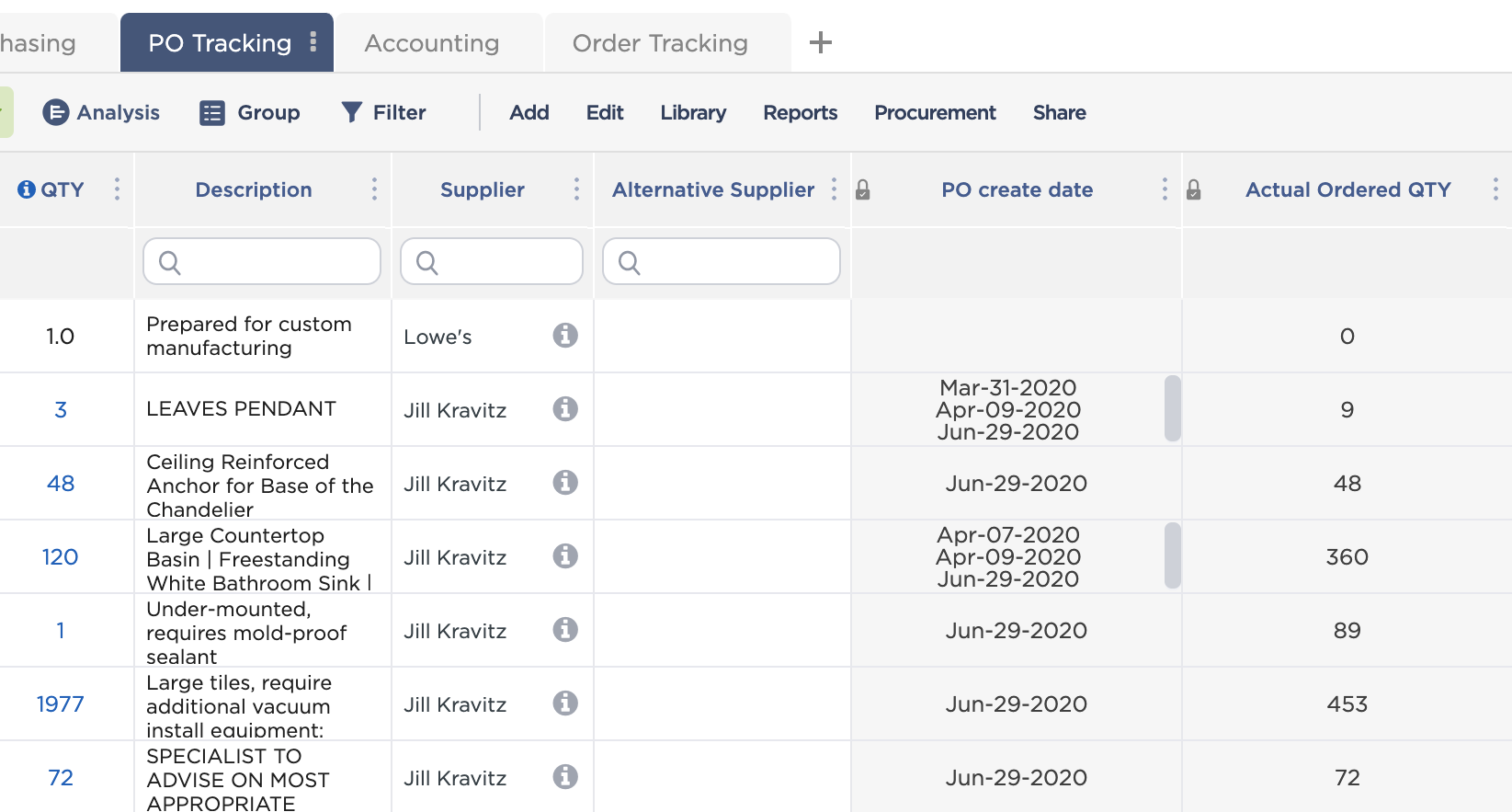

Speaking of ordering from a different supplier: You probably already have pre-negotiated prices with several suppliers. Unfortunately, even the most reliable vendors could be suffering from delays beyond their control. In that case, it’s a good idea to line up your backups.

In your procurement dashboard, you can create a column that indicates your second choice for a specific material. Keeping it visible means your procurement team won’t have to spend too much time figuring out where to go.

But where should you source from? Because 30% of building materials imported into the US is coming from China (not to mention raw materials that could be used for manufacturing in other countries), that presents a lot of vulnerability.

Harvard Business Review suggests adding sources “in locations not vulnerable to the same risks. The U.S.-China trade war has motivated some firms to shift to a “China plus one” strategy of spreading production between China and a Southeast Asian country such as Vietnam, Indonesia, or Thailand.”

HBR also recommends considering “a regional strategy of producing a substantial proportion of key goods within the region where they are consumed.” North America, for example, could start looking to Mexico and Central America for materials that are mostly sourced from China.

Improve visibility.

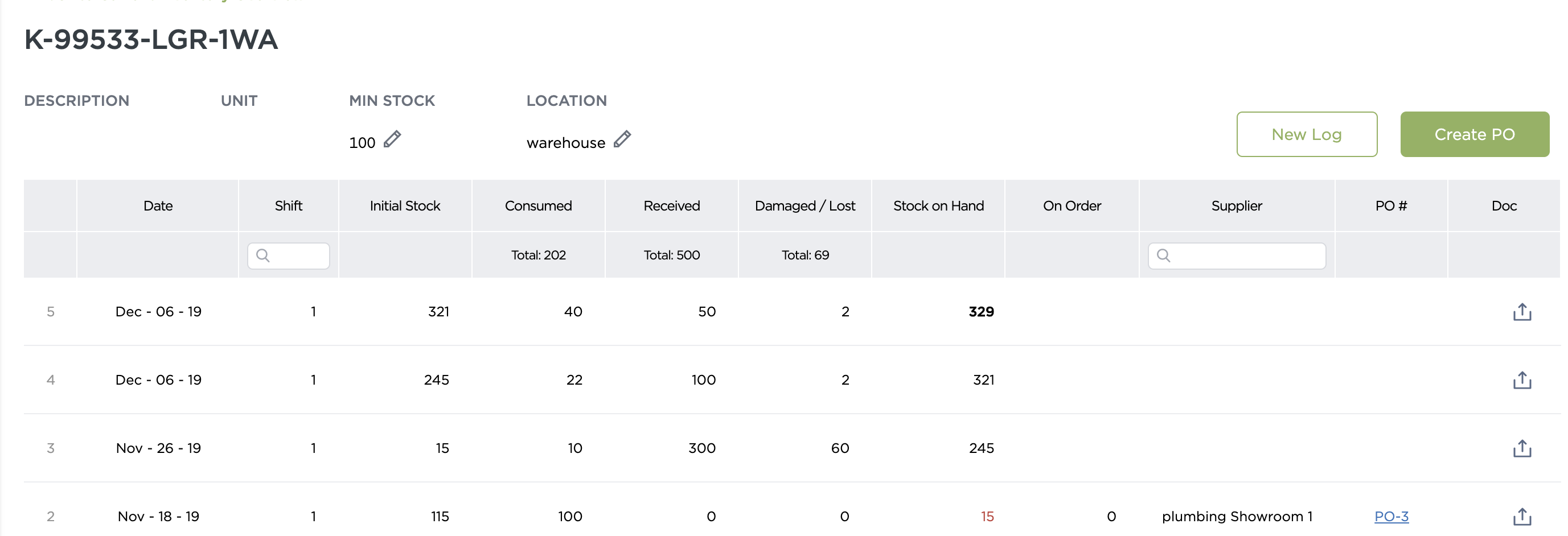

For large projects that regularly go through a huge amount of specific materials — like concrete for building roads — it’s particularly important to be on top of inventory.

In your Inventory section, you can keep track of how much material you still have on hand and how much is about to arrive, if any. You’ll get an automatic indication when your inventory is below a certain threshold, so you can place orders on time.

Manage FF&E specification, procurement, and product data at scale. Take on bigger projects with confidence and grow your firm with Fohlio. Schedule a demo or book a consultation with one of our account managers to explore these features today.

Image: Eaton Steel Bar Co., Michigan